Products & Services

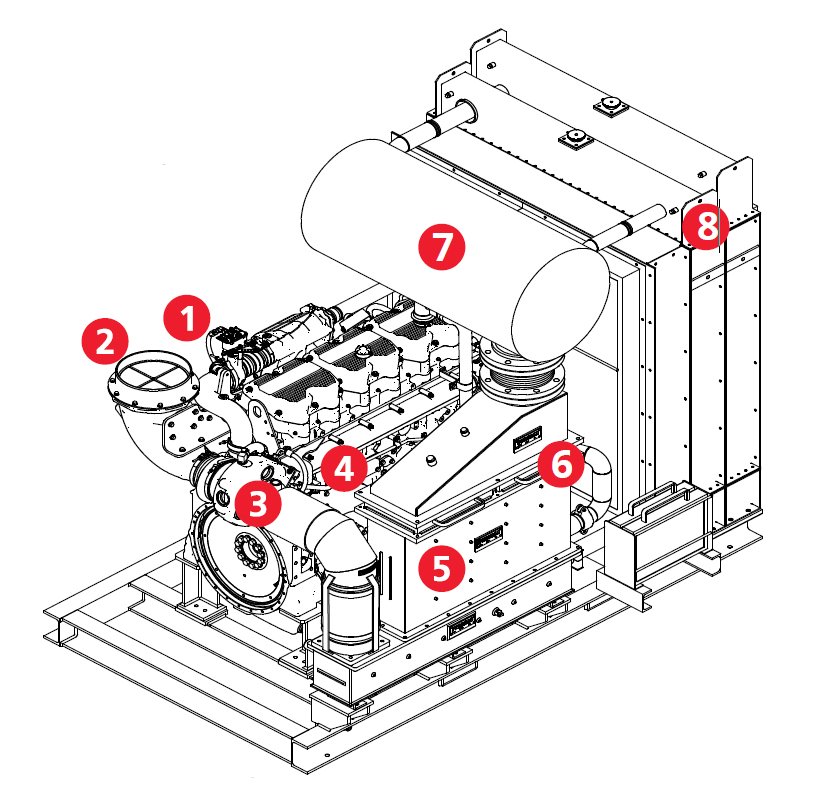

Pyroban Kit

PYROBAN PROTECTION CRITICAL CONSIDERATIONS

Potential ignition sources on unprotected diesel engines include electrical, mechanical or static sparks, overspeed or flame transmission from inlet or exhaust, and hot surfaces.

1. Air inlet shut-off Valve

Flammable gases in the atmosphere can be drawn in through the air intake along with air for combustion. This can result in flashbacks through the inlet and backfires in the exhaust.

If the engine consumes flammable gas mixed with air and diesel fuel, engine overspeed can occur, which can lead to the engine running out of control. This can result in catastrophic failure of the engine, creating unprotected ignition sources.

2. Air inlet flame arrestor

When Gas is ingested, there is risk of the engine misfiring, leading to unburnt fuel mixture entering the exhaust system. This can be detonated from the heat of the exhaust and ignite the surrounding (now flammable) atmosphere.

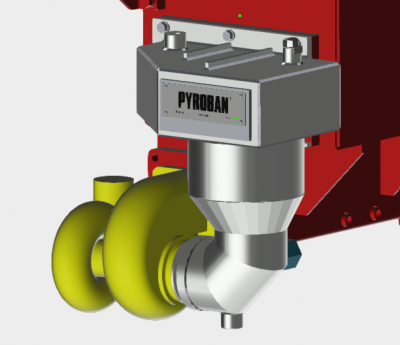

3. Water-cooled Turbocharger & Exhaust Manifold

Many surfaces on a diesel engine can exceed safe limits and become sources of ignition. These surfaces need to be protected to avoid the danger of explosion by ensuring surface temperature is below 200°C (T3).

4. Thermal control & treatment

Thermal signature of engines and ancillary parts can be further reduced using our proprietary thermal coatings.

5. Exhaust Gas Heat Exchanger

Cools the engine exhaust below 200°C (T3) in local ambient.

6. Exhaust Flame Traps

Prevents back fire from the explosion proof exhaust system. Can be eliminated by using our certified Ex-SCS™ system or Everclear™.

7. Spark Arrestor

Ensures that no exhaust-born hot particles escape into the atmosphere.

8. Radiator

A choice of industrial or marine solder dipped radiators providing additional cooling capacity and corrosion resistance is available.

Kit and Package solutions may also include:

- Ex Battery

- Ex Starter

- Ex Electronic Control System

- Ex Certified ECM and engine electrical system

- Enclosures

Certification

All Pyroban products are certified, with some having tri-certification to ATEX 2014/34/EU, IECEx and NEC 505/NEC 500.

EX Components

Components and control systems for use in hazardous areas.

Red Ex Line

Red Ex Line™ is a compact perimeter marking warning system fully ATEX certified to minimise risk for staff working in hazardous areas. There is one model for all Zones.

EX Solutions Consulting

As explosion protection consultants, we help OEMs and businesses solve their Ex certification requirements, whether it’s a one-off project or to develop an Ex certified (ATEX, IECEx, UKEx) version of their product so they can win business in hazardous area applications.

Blue EX Spot - Awareness Light

Blue Ex Spot™ is a compact driving path warning system fully ATEX certified to minimise risk for staff working in hazardous areas. There is one model for all Zones.

Ever Clear Exhaust Flame Arrestors

Ever Clear Exhaust (ECE) Flame Arrestors developed by Pyroban are a direct replacement for the plate type flame arrestors found in Pyroban explosion protected diesel engines.

EX SCS – Safety Control System For Atex Packages

Pyroban Ex SCS is our flagship Category 2G safety control system. The product has been developed as the successor to the ground breaking 3GP system, but addresses a number of industry problems to bring reduced installation and maintenance costs to our customers by combining flame arrestor elimination, safety shutdown and engine control in one flexible package.

PCS 2 – Safety Control System

Pyroban PCS2 is a passive protection system which allows diesel engines and power systems to be safely operated in a Zone 1 or Zone 2 certified hazardous area meeting the requirements of national and international regulations. The PCS2 system protects against engine overspeed, over temperature, loss of oil pressure and also has an emergency stop facility.

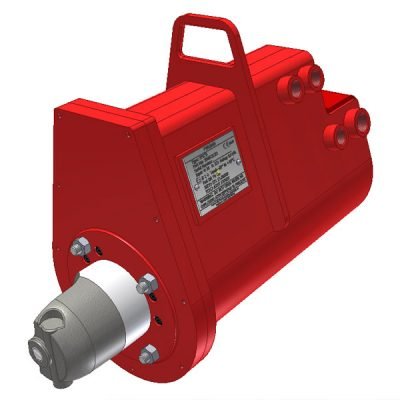

Air Intake Shut-off Valves For Diesel Engines

Air intake shut-off Valves from Pyroban – The SVH and SVD series of air inlet shutdown valves are an integral safety component for diesel engines. Their primary use is to shut off the air inlet supply to an engine to prevent a potential explosion.

Spark Arrestors – ATEX Approved

Pyroban has a comprehensive range of ATEX spark arrestors suitable for a wide range of applications. We supply three categories of spark arrestors to a variety of lengths, diameters, pipe sizes and power ranges, allowing you to find the spark arrestor which meets your specification.

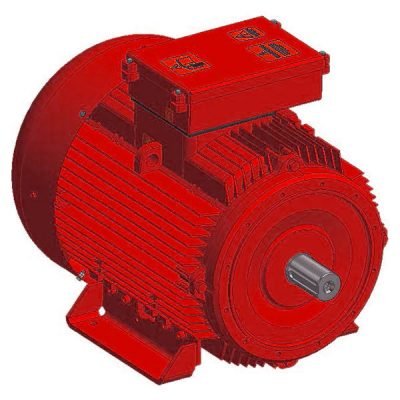

ATEX Alternator (Battery Charging) – Explosion Protection

Our battery charging explosion protection (flameproof) alternator (FPA) range is designed for a reliable output in the most arduous of environments. The fully enclosed, rugged and robust construction ensures protection against dirt, moisture and dust and provides a long service life.

ATEX Battery – Explosion Protection

The Pyroban explosion protection offshore battery is designed for use in hazardous areas and are corrosion resistant with a 316 stainless casing. The 12V and 24V units contain deep cycle batteries protected with a 50A MCB isolator. These ATEX batteries are not suited to engine cranking applications.

Bespoke Exd Enclosures

Our bespoke aluminium and steel Exd enclosures are available design to order. If you have a requirement to house starting contactors, battery chargers, or any arcing or sparking apparatus. we can design, supply and test the Exd enclosure and its contents.

ATEX Alternator (Power) – Explosion Protection

The explosion protection AC alternator (power) is Category 3G IECex and ATEX certified brushless, totally enclosed, fan-cooled, non sparking and twin bearing AC 400v Alternator with an output of 60kVA or 80kVA.

Engine Controls ATEX Packages

Pyroban provides Engine Control Solutions for hazardous areas. The Pyroban Ex SCS can provide basic diesel engine control functions, but we have also developed other solution

ATEX Starter Motors – Explosion Protection

Pyroban offers a range of explosion protection (ATEX) starter motors for both materials handling and diesel engine applications. The FPS (Flame Proof Starter) range is certified for use in an ATEX Zone 2 hazardous area.

Sales & Marketing

Office

Aerodyn Group

Main Office (1257403-W)

-

N-3-01, The Gamuda Biz Suites

Jalan Anggerik Vanilla 31/99,

Kota Kemuning, 40460 Shah Alam

Selangor Darul Ehsan

Workshop

-

No. 56, Jalan Tambur 33/19

Shah Alam Technology Park

Seksyen 33

40400 Shah Alam

Selangor Darul Ehsan