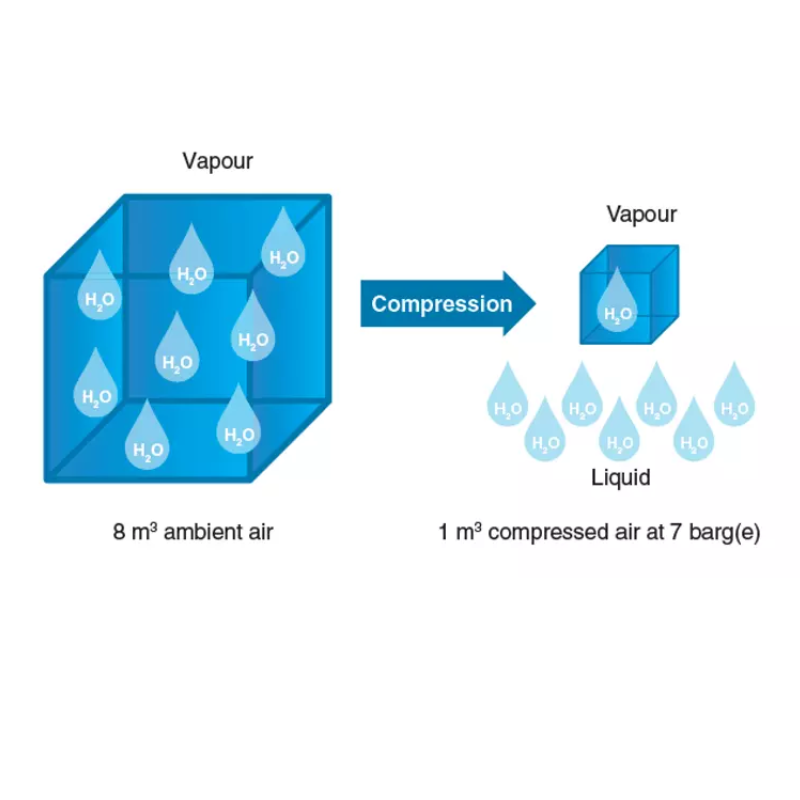

If you've worked with an air compressor, you've likely noticed the air is saturated with moisture. This is because water, in contrast to air, is incompressible. The amount of moisture per volume unit increases when air is compressed, creating condensation. Our compressed air dryers are vital for removing this moisture, which can cause corrosion, quality issues, and microorganisms in your air system.